HLA supplies “Plug and Play” lifts providing your customers with a luxurious addition to their home. Our lifts are designed to be installed quickly in new or existing construction. With a dedicated service team and transparent maintenance options, HLA Hydraulic Lifts are the lifts of choice for Architects and Home Builders.

The home lift process begins with a solid project plan. Along the way interactions must take place between the relevant parties; HLA, the architect, the builder (or general contractor) and the homeowner. We also provide a detailed Site Preparation Checklist to all clients to ensure that there is no ambiguity with regards to pre-installation requirements.

SUPPORT TO ARCHITECTS

| CUSTOMISED DESIGNS | Cabin sizes using our hydraulic drive are 20% – 30% bigger with the same shaft size compared to traction lifts, giving you greater design freedom.

The additional space can be used to meet your design vision and needs. We can also give multiple entries making it possible to install our lifts in almost any orientation. We also support architects by providing detailed drawings and dimensions, lift renderings and BIM. |

| ULTIMATE FLEXIBILITY | Hydraulic lifts do not need load bearing walls and using our aluminum or steel shafts, can even be installed with little or no support of the civil structure.

This allows for greater building design integrity giving more value to your efforts. |

| INNOVATIVE TECHNOLOGY | With the help of our dynamic and innovative suppliers, we are able to offer completely integrated automation options and security features.

Our designer series touch screen panels will appeal to the most discerning of clients. |

| MODULAR SHAFT SYSTEMS | Modular aluminum or steel structures facilitate quicker installation either inside or outside the building.

In the event of retrofitting of a lift in view of a renovation, the lift can be installed quickly and with minimum hassles to the client due to minimal civil requirements. |

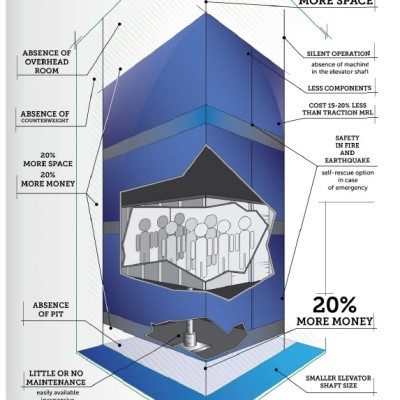

ADVANTAGES OF HLA HYDRAULIC LIFTS

| Parameters | Hydraulic Lift | Traction Lift |

| 20% – 30% MORE SPACE | • Smaller space requirement in the shaft due to counterweight-free design.

• Flexible machine room location • A great deal of design freedom for architects • No rooftop structure or deep pit is required • No constraints on doorways or the shape of the car |

• Smaller car due to the considerable space needed for the sheave assembly and counterweight, alternatively a larger shaft cross-section and head height

• Architectural design scope is very restricted |

| SAFER | • Emergency evacuation procedures are very simple and completely safe

• Much safer when used in earthquake zones • Safety during service and repair work, since there is no moving counterweight |

• Complicated, and in some respects hazardous, emergency evacuation procedures

• In an earthquake, the danger from drive components or the counterweight falling on the car |

| HIGHER PERFORMANCE | • Particularly high load ratings

• All vertical loads act in the shaft pit only • Blain Hydraulics technology and weight-optimization ensure an extremely attractive price/performance ratio • Precision controls and leveling scope for any type of building. |

• Poor load ratings

• Uneven leveling found in the Traction Lift – upto ± 75mm in low-rise buildings. |

| LESSER MAINTENANCE REQUIREMENTS | • Technically straightforward and familiar principle reduces the amount of installation work in the shaft

• Low-maintenance drive technology • No wear on pulleys and ropes • Replacement parts are seldom needed • Replacement parts are less expensive, not tied to a particular manufacturer, and available on the open market • Technicians can work on the drive from outside the shaft. They are consequently not exposed to any hazard and thus save time |

• Heavy wear on traction sheave and ropes.

• Complicated work procedures, and hazardous working situations. • Long repair and maintenance times. • With manufacturer dependent systems, the operator is “locked in“ for maintenance and repairs; independent service providers are ruled out |

| FLEXIBLE INSTALLATION | • Simple and economical assembly

• Hydraulic lifts are particularly suitable for projects where retrofitting is involved. • Our lifts are designed as per available space requirements of the homeowner. |

• The drive system in the shaft head is difficult to access and assembly work is hazardous.

• Shaft needs to be made exactly as per manufacturer specifications. |

| MORE VALUE | • For low-rise buildings, the cost effectiveness of hydraulic lifts is virtually unbeatable. | • Very high costs for service and replacement parts. |