POWER UNITS

Hydraulics & Lifting Aids provides hydraulic lift power units for any application; from small capacity home lifts to large cargo lifts. We can manufacture power units based on your component requirements or can perform necessary detailed calculations based on your lift data to select and provide a power unit to meet your specified requirements.

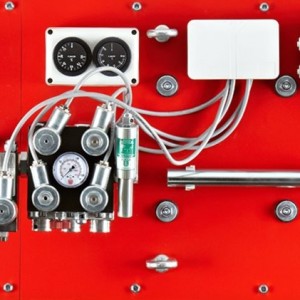

Power Units can be designed with Submersible Motors as well as Standard TEFC Motors. Generally, our power units are supplied with:

- Tank with Oil Level Indicator and Filler/Breather

- Blain Elevator Valve

- Screw Pump

- Ball Valve and Hand Pump

- Optional Pre-Wired Junction Box

OPTIONAL FEATURES

- Oil Cooler – necessary when the number of trips per day is above the maximum rated daily trip count, causing the oil to heat up beyond the heat dissipation rate of the system.

- Pressure Sensor Switch – DL switches are used to signal a drop in hydraulic pressure below the normal operating pressure. DH switches are used to signal hydraulic pressure above the normal operating pressure.

- Vibration Isolator Anchoring Kit – allows for securing the power unit to the machine room floor while isolating the unit from transferring noise and vibration through the building.

- Emergency Power Coil – Should there be an interruption of the main power to the elevator, the emergency lowering coil EN, fed by an emergency 12 V DC or 24 V DC supply, enables a command to be given from the car or elsewhere to lower the car to the floor below.

- Explosion Proof Solenoids – For use with equipment and protective systems, intended for use in potentially explosive atmospheres-directive 94/9 EG. EC-type-examination certificate-number: PTB 02 ATEX 2193 X. Compliant with EN 50014: 1997 and EN 50028: 1987.

- Pressure Compensated Down Flow Guide – recommended for use to maintain down speed within close limits when empty to full loading ratios of the elevator exceed 1:2.5. The CX is interchangeable with the standard flow guide and is selectable using the same chart.

- Micro Levelling Drive – The Blain Micro Drive for hydraulic elevators consists of a small motor, pump and valve unit in one assembly. Exact floor stops and relevelling operations are achieved with low electrical power requirement, low noise levels and no unnecessary heating of the oil. The MD unit is mounted on or under the cover of the main hydraulic power unit, using the same oil source. It can also be used to slowly move the car independently of the main drive during installation or in an emergency.

QUALITY ASSURANCE

Quality Control is an essential and integral part of our manufacturing process. Every phase of production is monitored to assure that each power unit is assembled in accordance with engineering and shop order specifications to meet our quality standards. From the initial process of raw material, to the final process of placing the product on the truck, you can be assured that our quality standards are met and that the finished product meets your requirements.

GENERAL DETAILS

Tank Size required is based on space required for pump & motor assembly and amount of oil required for operation.

The tank is constructed with a 3 mm steel body, a removable 5 mm steel lid and an additional inspection cover which can be removed to inspect the internal components during lift operation. Power Units are designed to fit through a standard room door.

Power Units are fitted with Blain control valves. The valves are mounted on separate couplings making it extremely simple to remove the valve for maintenance, without the need to remove the lid.

We recommend MAK Hydrol ISO VG 68 Hydraulic Oil.