POWER UNITS

Hydraulics & Lifting Aids provides hydraulic lift power units for any application; from small capacity home lifts to large cargo lifts. We can manufacture power units based on your component requirements or can perform necessary detailed calculations based on your lift data to select and provide a power unit to meet your specified requirements.

Power Units can be designed with Submersible Motors as well as Standard TEFC Motors. Generally, our power units are supplied with:

- Tank with Oil Level Indicator and Filler/Breather

- Blain Elevator Valve

- Screw Pump

- Ball Valve and Hand Pump

- Optional Pre-Wired Junction Box

OPTIONAL FEATURES

- Oil Cooler – necessary when the number of trips per day is above the maximum rated daily trip count, causing the oil to heat up beyond the heat dissipation rate of the system.

- Pressure Sensor Switch – DL switches are used to signal a drop in hydraulic pressure below the normal operating pressure. DH switches are used to signal hydraulic pressure above the normal operating pressure.

- Vibration Isolator Anchoring Kit – allows for securing the power unit to the machine room floor while isolating the unit from transferring noise and vibration through the building.

- Emergency Power Coil – Should there be an interruption of the main power to the elevator, the emergency lowering coil EN, fed by an emergency 12 V DC or 24 V DC supply, enables a command to be given from the car or elsewhere to lower the car to the floor below.

- Explosion Proof Solenoids – For use with equipment and protective systems, intended for use in potentially explosive atmospheres-directive 94/9 EG. EC-type-examination certificate-number: PTB 02 ATEX 2193 X. Compliant with EN 50014: 1997 and EN 50028: 1987.

- Pressure Compensated Down Flow Guide – recommended for use to maintain down speed within close limits when empty to full loading ratios of the elevator exceed 1:2.5. The CX is interchangeable with the standard flow guide and is selectable using the same chart.

- Micro Levelling Drive – The Blain Micro Drive for hydraulic elevators consists of a small motor, pump and valve unit in one assembly. Exact floor stops and relevelling operations are achieved with low electrical power requirement, low noise levels and no unnecessary heating of the oil. The MD unit is mounted on or under the cover of the main hydraulic power unit, using the same oil source. It can also be used to slowly move the car independently of the main drive during installation or in an emergency.

QUALITY ASSURANCE

Quality Control is an essential and integral part of our manufacturing process. Every phase of production is monitored to assure that each power unit is assembled in accordance with engineering and shop order specifications to meet our quality standards. From the initial process of raw material, to the final process of placing the product on the truck, you can be assured that our quality standards are met and that the finished product meets your requirements.

GENERAL DETAILS

Tank Size required is based on space required for pump & motor assembly and amount of oil required for operation.

The tank is constructed with a 3 mm steel body, a removable 5 mm steel lid and an additional inspection cover which can be removed to inspect the internal components during lift operation. Power Units are designed to fit through a standard room door.

Power Units are fitted with Blain control valves. The valves are mounted on separate couplings making it extremely simple to remove the valve for maintenance, without the need to remove the lid.

We recommend MAK Hydrol ISO VG 68 Hydraulic Oil.

Hydraulic Cylinders

Hydraulics & Lifting Aids manufactures cylinder with precision equipment, experienced personnel and knowledgeable engineering to comply with the standards required to produce a quality product. Additionally, the following equipment is included with the cylinder units:

- Cylinder extension stand with guide bush and one clamping bracket (Either Independent or depending on the DBG)

- Three Cylinder clamping brackets (Either Independent or depending on the DBG)

- Pit Steel equipment include a Pit Tray with the Base Hitch suitable for our car frames.

- Hose Rupture Valve

We have many sizes of cylinders to meet your specific requirements and can manufacture cylinders based on your component or can perform necessary detailed pressure and buckling calculations based on your lift data to select and provide a cylinder to meet your specified requirements.

Our cylinders are single stage load return type, consisting of a single piston in a cylinder with gland at the upper end where the piston collapses into the cylinder. Single stage jacks are designed for guided applications only, where the cylinder is rigidly supported and guided through the use of guide rails and guide shoes.

QUALITY ASSURANCE

Quality Control is an essential and integral part of our manufacturing process. Every phase of production is monitored to assure that each cylinder is assembled in accordance with engineering and shop order specifications to meet our quality standards. From the initial process of raw material, to the final process of placing the product on the truck, you can be assured that our quality standards are met and that the finished product meets your requirements.

GLAND DETAILS

The cylinder glands are designed for ease of disassembly when servicing. An oil collection groove is provided and arrangement is included to connect an oil drain line to catch and reclaim oil that collects in the groove (it is necessary for the piston to carry a film of oil through the packing in order to provide smooth and quiet operation).

PISTON DETAILS

The upper end of the chrome plated piston is provided with a drilled and tapped hole to receive a standard bolt for attachment to the platen plate. The bottom of the piston is closed with a stop plate to prevent the piston from leaving the cylinder.

CYLINDER DETAILS

Our standard honed cylinders are provided with a bleeding port to purge air during commissioning. A threaded inlet is provided for fixing the hydraulic hose. All cylinders are thoroughly cleaned and inspected. They are then painted with multiple coats of epoxy paint to ensure a long, corrosion free service life.

BLAIN HYDRAULICS – COMPANY PROFILE

Since 1970 Blain hydraulics has specialized in the design and manufacture of the finest and safest control valves for hydraulic elevators. With over half a million Blain valves in operation worldwide, we are a leading company offering a wide spectrum of accessories and solutions for the elevator industry.

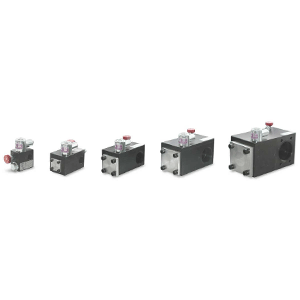

CONTROL VALVES

The BLAIN EV program includes the widest range of options offered to the elevator industry for high performance passenger service. Easy to install, EV‘s are smooth, reliable and precise in operation throughout extreme load and temperature variations.

Available port sizes are ¾”, 1½”, 2″ and 2½” pipe threads, depending on flow. EV‘s start on less than minimum load and can be used for across the line or wye-delta starting. According to customers’ information, valves are factory adjusted ready for operation and very simple to readjust if so desired. The patented up levelling system combined with compensated pilot control ensure stability of elevator operation and accuracy of stopping independent of wide temperature variations.

EV valves include the following features essential to efficient installation and trouble free service:

| · Simple Responsive Adjustment | · Self-Cleaning Pilot Line Filters |

| · Temperature and Pressure Compensation | · Self-Cleaning Main Line Filter (Z-T) |

| · Solenoid with Connecting Cables | · Built-in Turbulence Suppressors |

| · Pressure Gauge and Shut Off Cock | · 70 HRc Rockwell Hardened Bore Surfaces |

| · Self-Closing Manual Lowering | · 100% Continuous Duty Solenoids |

| Technical Data: | ¾“ EV | 1 ½“ and 2“ EV | 2 ½“ EV | |

| Flow Range: | l/min | 10 – 125 | 30 – 800 | 500 – 1530 |

| Pressure Range: | bar | 5 – 100 | 3 – 100 | 3 – 68 |

| Press. Range CSA: | bar | 5 – 100 | 3 – 70 | 3 – 47 |

| Burst Pressure Z: | bar | 575 | 505 | 340 |

| Pressure Drop P–Z: | bar | 6 at 125 lpm | 4 at 800 lpm | 4 at 1530 lpm |

| Weight | kg | 5 | 10 | 14 |

| Oil Viscosity: | 25-60 mm²/sec. at 40°C (15-35 cSt. at 120°F) | |||

| Solenoids AC: | 230 V/0.18 A, 50/60Hz | |||

| Solenoids DC: | 24 V/1.1 A | |||

| Max. Oil Temperature: | 70°C (158°F) | |||

| Insulation Class, AC and DC: | IP 68 | |||

Download PDF

Datasheet

EV 100 en (0 downloads)

Troubleshooting

EV Troubleshooting – en (3835 downloads)

Quick Guide

EV Quick Guide – en (3199 downloads)

Spare Parts

EV – KV Spare Parts – en (2424 downloads)

Internal Leakage

EV Dichtsatz – en (1835 downloads)

Range

EV0 (1 ↑ 2 ↓)

Up:

Up to 0.16 m/s. 1 Up Speed. Up Start is smooth and adjustable. Up Stop is by de-energising the pump-motor.

Down:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. All down functions are smooth and adjustable.

EV1 (1 ↑(Soft Stop) 2 ↓)

Up:

Up to 0.16 m/s. 1 Up Speed. Up to 0.4 m/s by over-travelling and levelling back down. Up Start is smooth and adjustable. Up Stop is smooth and exact through valve operation whereby the pump must run approx. ½ sec. longer through a time relay.

Down:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. All down functions are smooth and adjustable.

EV10 (2 ↑ 2 ↓)

Up:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. Up Start and Slow Down are smooth and adjustable. Up Levelling speed is adjustable. Up Stop is by de-energising the pump-motor.

Down:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. All down functions are smooth and adjustable.

EV100 (1 ↑ 2 ↓) – fully adjustable

Up:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. All ‘up’ functions are smooth and adjustable. Up Levelling speed is adjustable. Up Stop is smooth and exact through valve operation whereby the pump must run approx. ½ sec. longer through a time relay.

Down:

Up to 1.0 m/s. 1 Full Speed and 1 Levelling Speed. All down functions are smooth and adjustable.

KV Series

KV ½” solenoid valves are designed for small hydraulic lifts operating at speeds up to 0.16 m/s depending on the valve selected. The smooth and accurate ride characteristics of the KV2S valve which includes ‘soft stop’ in both directions, render it highly suitable for quality home lifts and lifts for the handicapped.

| Flow Range: | 5-80 l/min. |

| Oil Viscosity: | 25-60 cSt. at 40°C (15-35 cSt. at 120°F) |

| Solenoids AC: | 230 V/0.18 A, 50/60 Hz |

| Solenoids DC: | 24 V/1.1 A |

| Ports: | P Pump, Z Cylinder and T Tank all G½” |

| Insulation Class, AC and DC: | IP 68 |

| Pressure Range: | 8-100 bar |

| Burst Pressure: | 500 bar |

| Max. Oil Temperature: | 70°C (158°F) |

KV Series Range

KV1P (1 ↑ 1 ↓)

Up:

One up speed, 0.16 m/s max. Up start has built-in damping. Up stop has no damping (pump stops).

Down:

One down speed, 0.16 m/s max. Down start has adjustable damping. Down speed is adjustable. Down stop has built-in damping.

KV1S (1 ↑(Soft Stop) 1 ↓)

Up:

One up speed, 0.16 m/s max. With soft stop, or 0.4 m/s max. With over-travel and relevelling. Up start has built-in damping. Up stop has adjustable damping (delayed pump stop required).

Down:

One down speed, 0.16 max. Down start has adjustable damping. Down speed is adjustable. Down stop has built-in damping.

KV2P (1 ↑ 2 ↓)

Up:

One up speed, 0.16 m/s max. Up start has built-in damping. Up stop has no damping (pump stops).

Down:

Two down speeds, 1 m/s max. Down start has adjustable damping. Fast down speed and levelling speeds are adjustable. Slow down and stop have built-in damping.

KV2S (1 ↑(Soft Stop) 2 ↓)

Up:

One up speed, 0.16 m/s max. With soft stop, or 0.4 m/s max. With over-travel and relevelling. Up start has built-in damping. Up stop has adjustable damping (delayed pump stop required).

Down:

Two down speeds, 1 m/s max. Down start has adjustable damping. Fast down speed and levelling speeds are adjustable. Slow down and stop have built-in damping.

GV Series

For hydraulic car parking ports and material lifting platforms. The Blain car parking platform valve can be used in car parking applications where the platform needs to be raised above the ground to accommodate another car below the port. Alternatively this valve is also ideal for lifting material, cargo and suitable for dumbwaiters and goods lifts. The valve offers single up speed and adjustable down speed.

| Flow Range: | 1-24 l/min. |

| Oil Viscosity: | 25-60 cSt. at 40°C (15-35 cSt. at 120°F) |

| Solenoids AC: | 230 V/0.18 A, 50/60 Hz |

| Solenoids DC: | 24 V/1.1 A |

| Ports: | P Pump, Z Cylinder and T Tank |

| Insulation Class, AC and DC: | IP 68 |

| Pressure Range: | 8-130 bar |

| Burst Pressure: | 600 bar |

| Max. Oil Temperature: | 70°C (158°F) |

HX – MX – DOWN VALVES

HX are manually operated down valves, adjustable in their down speed. They close automatically upon release. They can be used for emergency manual lowering or in combination with the EV down valve to achieve an over-speed of the elevator for testing the pipe rupture valve.

MX are solenoid operated down valves, adjustable in their acceleration, down speed and deceleration. They can be used for the revision or inspection travel of the elevator or as a particularly slow down speed valve in addition to the two down speeds of the EV valve to obtain extremely exact floor stops.

L10 (UCM – A3) PRESSURE LOCK VALVE

The L10 Pressure Lock Valve is a solenoid operated check valve designed for hydraulic elevators and includes a self-closing manual lowering valve. Its purpose is to allow free flow of oil from the pump unit A to the cylinder B for upward travel and to prevent fl ow in the reverse direction from B to A until an electrical signal is given to the solenoid.

Installed in the main cylinder line directly adjacent to the main elevator control valve, the L10 can be employed as a safety back up valve to the down system of the main control valve to prevent unwanted down movement of the elevator should an electrical or mechanical malfunction occur in the main control valve.

Another application of the L10 is to reduce the amount of bounce in a hydraulic elevator system due to the compressibility factor of oil between the cylinder and the control valve, by mounting the L10 directly onto the cylinder connection. A Slack Rope Valve LK for roped elevators (e.g. 2:1 indirect transmission) is optional. It prevents the slack rope condition caused by the lowering of the ram when the car is suspended in the safeties or resting on the buffer.

L20 (UCM – A3) PRESSURE LOCK VALVE

The L20 Pressure Lock Valve is a solenoid operated check valve designed for hydraulic elevators and includes a self-closing manual lowering valve. Its purpose is to allow free flow of oil from the pump unit to the cylinder for upward travel and to prevent flow in the reverse direction from the cylinder to pump until an electrical signal is given to its solenoid.

The L20 is to be directly mounted on a Blain EV ¾” valve at the cylinder port without the need of any adapters. It can be either used as a standalone safety valve by docking on an existing Blain EV valve with separate tank line (for modernizing old installations) or can be used as an integrated safety valve together with Blain’s EVL valve without the need of separate tank connection.

Installed in the main cylinder line directly integrated with the main elevator control valve, the L20 can be employed as a safety back up valve to the down system of the main control valve to prevent unwanted down movement of the elevator should an electrical or mechanical malfunction occur in the main control valve (UCM case).

A Slack Rope Valve LK for roped elevators (e.g. 2:1 indirect transmission) is optional. It prevents the slack rope condition caused by the lowering of the ram when the car is suspended in the safeties or resting on the buffers.

RUPTURE VALVE – R10

The rupture valve R 10 can be mounted in any position directly onto the cylinder inlet connection Z. In the event of failure in the main cylinder line or where the down speed exceeds allowable limits, the R 10 valve closes, bringing the car to a smooth stop.

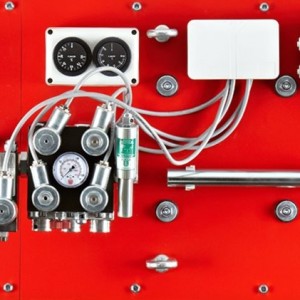

MRL-H SERVICE UNIT

The MRL-H has been designed for servicing and rescuing operations of machine room-less (MRL) hydraulic elevators remotely by having easy outside access, without needing to be in the pit. Many functional valves such as self-closing manual lowering valve, hand pump, slack rope valve, pressure relief valve, manual lowering speed adjustment, ball valve as well as a manometer have been added to a compact body. MRL-H can be located up to 6 meter (19 feet) away and 5 meter (16 feet) high from the main power unit to a convenient location for easy access.

SUBMERSIBLE PUMPS & MOTORS

SB Motori submersible single and 3 phase motors are specifically designed for immersion in oil to work with submersible screw pumps and meet the requirements of low noise level and high efficiency in hydraulic lifts.

SEIM screw pumps are specifically designed for immersion in oil to work with hydraulic lifts and meet the requirements of low noise level, high efficiency and low pulsation with flow up to 900 l/m.

SERVICE AND INSTALLATION TOOLS

VALVE TROUBLESHOOTING KIT

This kit provides parts commonly required during control valve service

Contains: Valve Catalog, Troubleshooting Guide, USB Drive with Android phone cable, Wrench Kit and Valve Seal Kit – all neatly packaged in an easy to carry pouch for on-site work.

CYLINDER LIFTING CLAMP

These clamps are designed to lift and hold hydraulic cylinders safely during installation. Constructed of formed bar steel for light weight and easy handling. These clamps are fitted with shackles for lifting and tensioning bolts for applying pressure around cylinder tube.

PORTABLE OIL FILTRATION SYSTEM

Our portable oil filtration system is a self-contained unit designed primarily to filter hydraulic oil. It can also be used as a transfer pump.

The system is mounted on a heavy duty trolley with an oil collecting pan for easy mobility. Plug the provided power cord into the 230V AC power supply, place the inlet and outlet pipes in the appropriate tanks, and open the ball valves, then switch on the power.

Replacement filters are available.

OIL TRANSMISSION LINE COMPONENTS

These include:

- Hydraulic Hose with end fittings

- Hose Adaptors, Elbows and Tee Couplings

- Shut-off Valves

- Pipe Clamps required for efficient hose routing.

- Washers, O-Rings and Seals of various sizes.