Composite Hoses

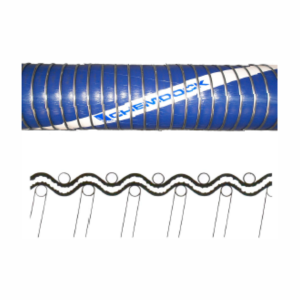

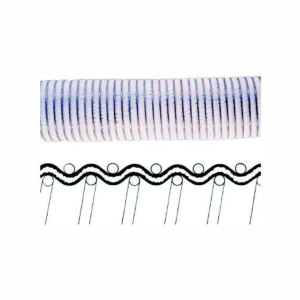

Composite hoses are manufactured on the mandrel wrapped principle.

The hose consists of an inner wire spiral upon which layers of fabric and film are wrapped, and bound with an external wire spiral. The tension between each wire spirals gives the hose its pressure capability.

The heart of a composite hose is in the materials selection. Fabric and film materials used include Polypropylene, Polyester and Polyamide. The wire helixes can be of galvanised steel, aluminium, stainless steel or polypropylene coated steel.

The final selection of the materials depends upon the application for the hose.

Hydraulics & Lifting Aids offers a wide variety of composite hoses quickly assembled and tested to meet customer urgency by maintaining a large inventory of hoses as well as end fittings. As with all our products, we rely on the world’s most trusted manufacturer,Radcoflex.

Advantages of Radcoflex Composite Hose

• Composite hose assembly is lightweight and kink proof.

• Electrical continuity can be maintained for transfer of hydrocarbons.

• Ability to withstand the harshest acids / chemicals.

• High flexibility for easier handling.

• Multi-layer construction prevents catastrophic failures.

• Flexibility is maintained at very low and even cryogenic temperatures.

• The hose assembly is fatigue free and do not age.

• Fastest delivery compared to competitors.